We provide ODM(Original Design Manufacturing) and OEM(Original Equipment Manufacturing) services that design, develop and manufacture original products according to customer's needs. We make full use of our knowledge and experience to propose the best ideas possible from a professional point of view.

Since manufacturing takes place in our own factory domestically, we offer the best quality and production schedule, and your confidentiality will be kept safe.

Furthermore, by utilizing the Braveridge Platform, it is possible to shorten the development lead-time and reduce development costs.

ODM

ODM

Why we are chosen

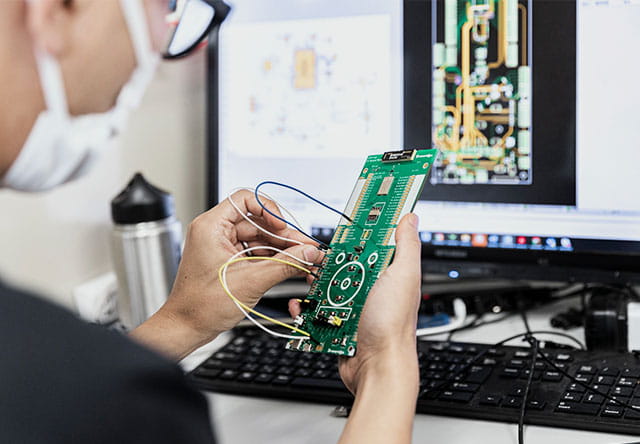

Braveridge provides one-stop solution to product planning, design development, and manufacturing of IoT. Also one-stop support from RF modules used for IoT to IoT devices and platforms.

We make the best use of our professional knowledge through years of experiences and our own IoT platform that accelerates IoT system development, which lead your IoT system to commercialize in the shortest time.

From Development to Manufacturing

Abundant knowledge and feedback from the field

When we undertake development and manufacturing contracts, we will carry out the whole task from development to manufacturing in-house consistently. Thanks to our factory in Japan, we receive live voices of the manufacturing site on top of years of experiences in the industry and know-how in the challenges of creating a large number of various products. Such products are born only because we value knowledge, experience, and the everyday voices of the field.

ODM Policy

- Think first and foremost of what the customer wants to achieve.

- Think of how that can be achieved.

- The goal is "Mass Production".

- Keep positive attitude towards the common goal while collecting information and making each discussion productive.

- Always propose ideas other than what are requested.

Our Strengths in Design

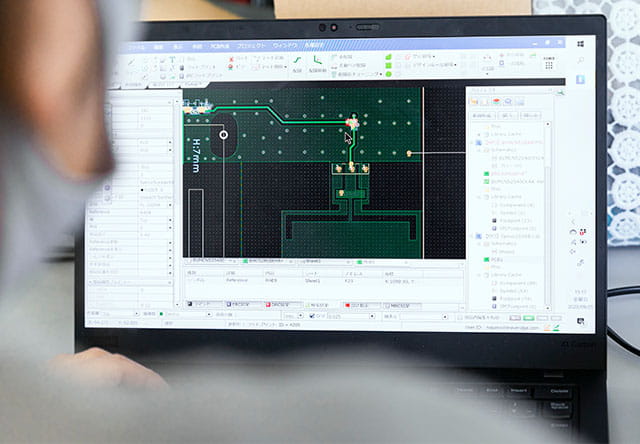

- Wireless Communication Design (Bluetooth®LE, LTE, LTE-M, various LPWA, etc..)

- IoT Network Design with Wireless Communication

- Charge and Discharge Design with Batteries etc.

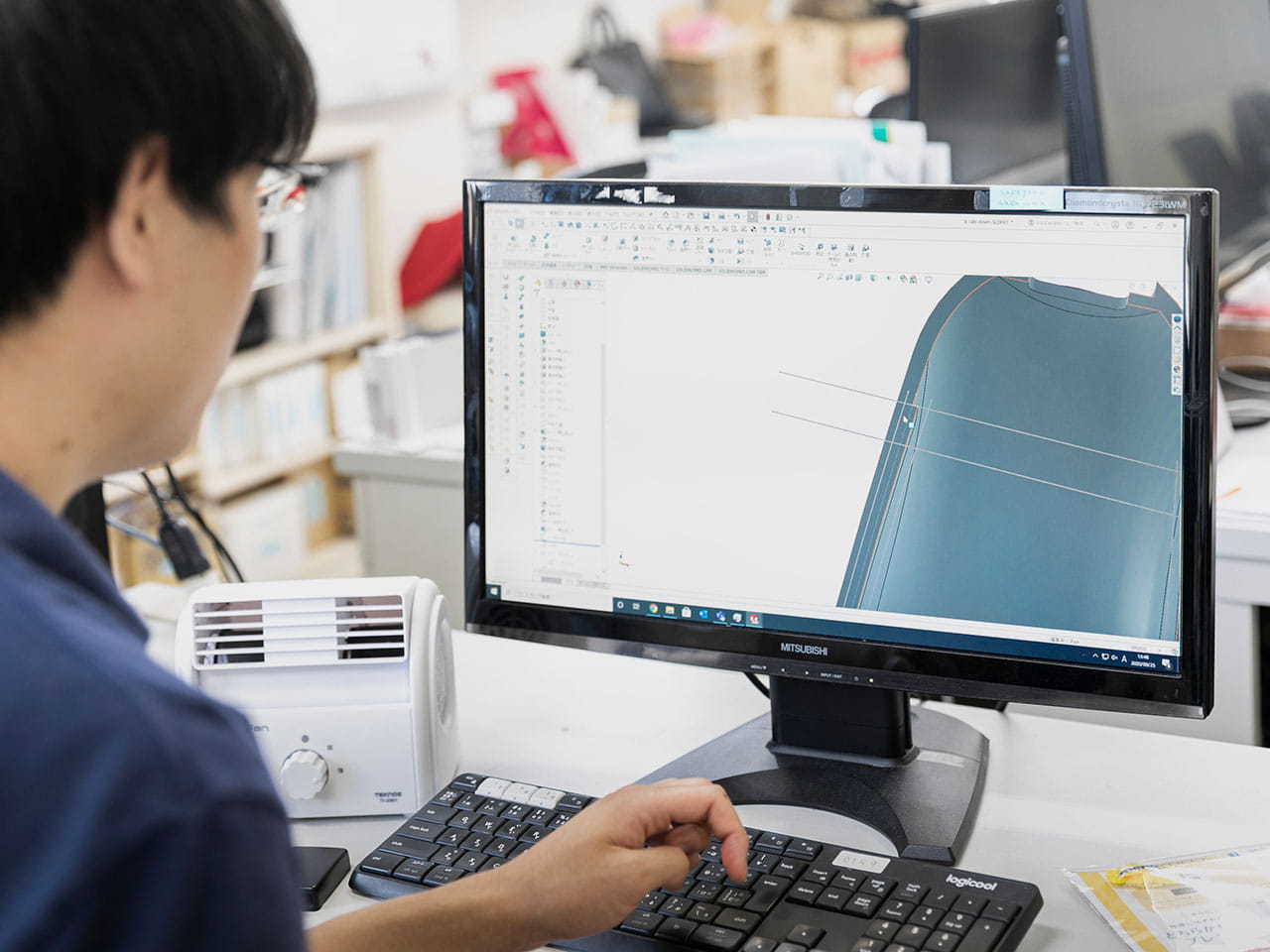

- Mold Design and Industrial Design

- VE (Value Engineering) Design

Flow of the Development and Manufacturing Contract

Conduct an Interview

Interviews will be conducted with the client, collecting all information as specifically as possible on what they want to achieve. With our expertise and experiences, we will offer the best to materialize the plan.

Quotation, Contract, and Placing Orders

Based on the specifications and implementation plans discussed from the interviews, approximate schedule, quotations, and trade conditions etc. will be presented.

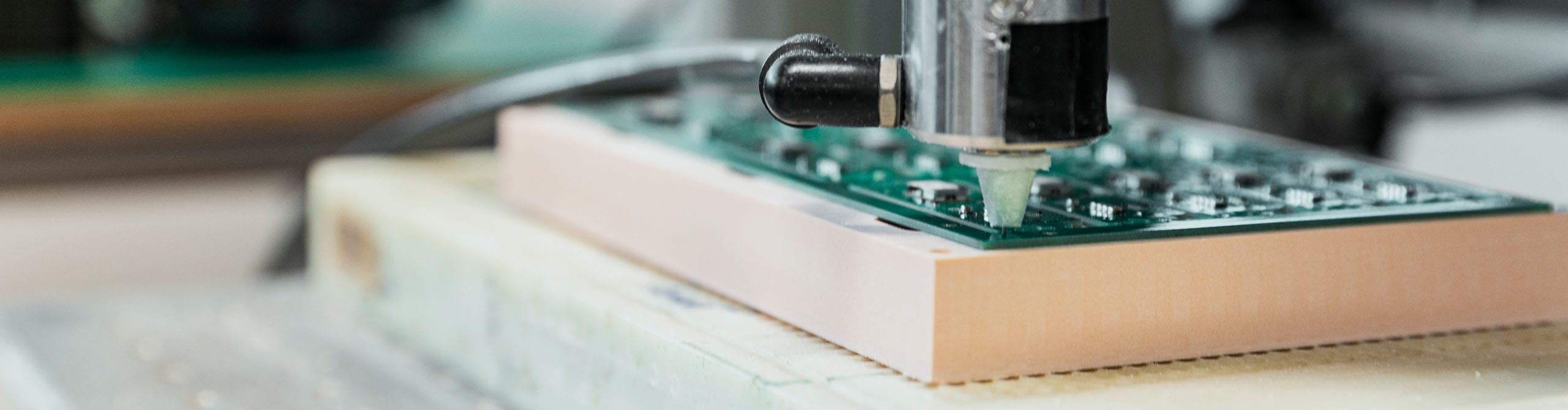

Development, Prototype, and Evaluation

After receiving the order, we make a start with designing and development, and finally evaluated with a prototype if the customer's requirements are met. The trial run will be repeated which confirms the required specifications can be achieved.

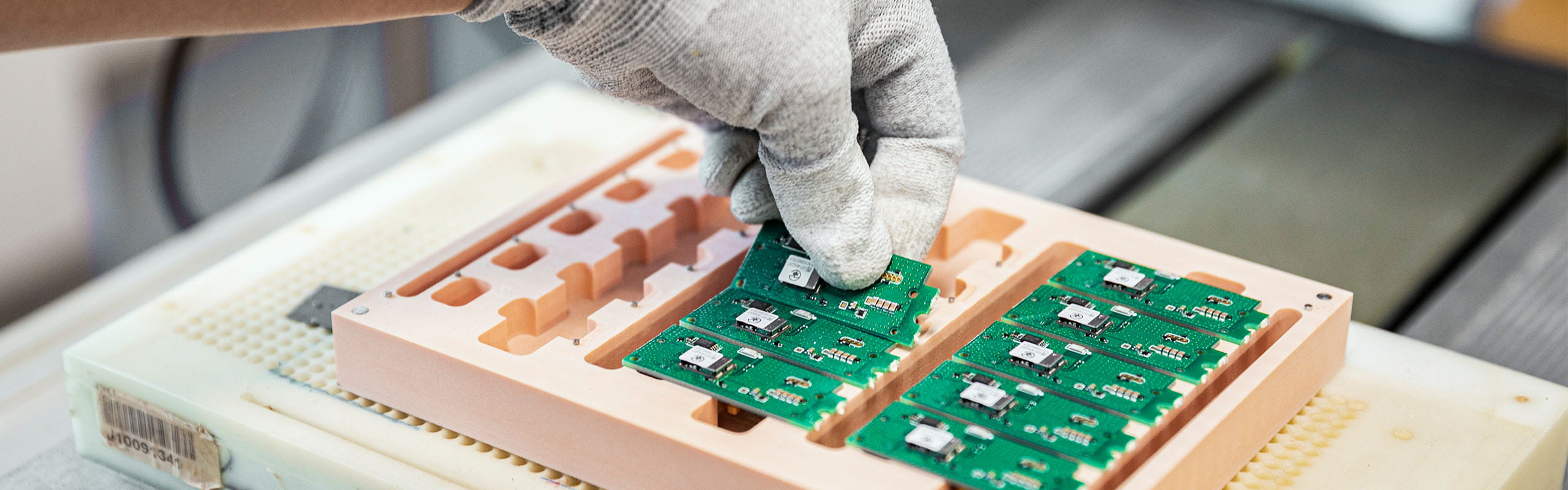

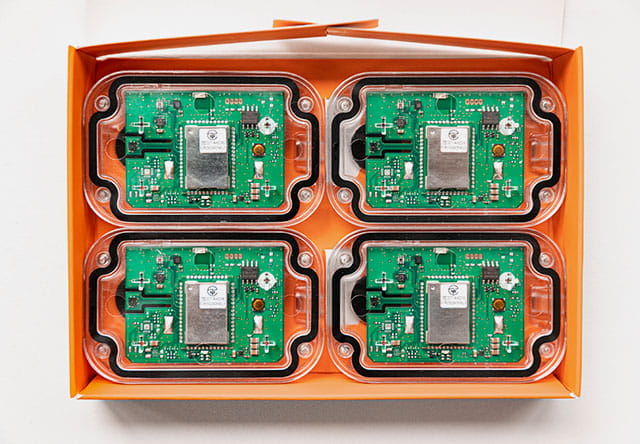

Preparation for Mass Production

We will make various preparations for mass production.

Mold arrangement, gathering materials for mass production, and jig preparation etc.

Production & Inspection, Completion & Shipment

Assembly is processed at our factory in Japan. Jigs for production and inspection on the production lines are also manufactured in-house, which makes us well equipped to handle complicated assembly and inspection.

Consultation of Development and Manufacturing Contract

Please check the following prerequisites when making inquiries:

- Payment terms: Full advance payment for development costs.

- Minimum Order Quantity

- Meeting Conditions (Tokyo, Fukuoka, or teleconference)

- Consultations for projects followed by Mass production only (we do not take inquiries for prototype only)

- Credit Check