Jig designs are created through the wealth of experiences from producing countless varieties of products and a high level of commitment to quality.

ITOSHIMA FACTORY

Braveridge Itoshima Factory located in Itoshima city, Fukuoka, procures materials, assembles, inspects, and delivers products.

Located conveniently 15 minutes away from the head office, we are able to provide high-quality products through detailed discussions with the development team from the very initial designing stage.

At the factory, we are also promoting conversion to a smart factory with the employment of our own products.

| Factory Name |

Braveridge Co., Ltd. Itoshima Factory |

|---|---|

| Location |

1999-19 Higashi Itoshima City, Fukuoka Prefecture 819-1122 |

| TEL / FAX |

TEL: 092-331-8181 / FAX: 092-331-8182 |

| Beginning of Operation |

November, 2017 |

| Site Area |

3824.48 ㎡ |

| Manufacturing Plant |

PCB Inspection, Assembly, Completion Inspection, Packing *SMT mounting is outsourced to a cooperating factory (quality assurance agreement has been concluded) |

| Production Capacity |

Approximately 100,000 units per month Calculated based on past results, varies depending on the product. |

|---|---|

| ISO |

ISO9001: 2015 version certified |

| Other Certification, Registration |

MFi Manufacturing Licensee |

| List of Equipment Owned by us |

Automatic Soldering Equipment |

5 Strengths for

Itoshima Factory

Braveridge not only offers development and manufacturing contract (ODM, OEM) services that meet the needs of customers, but also BMS (Braveridge Manufacturing Services) services that adopt the resources of Itoshima Factory.

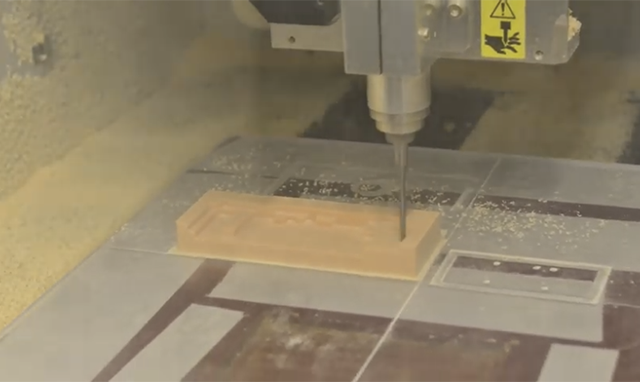

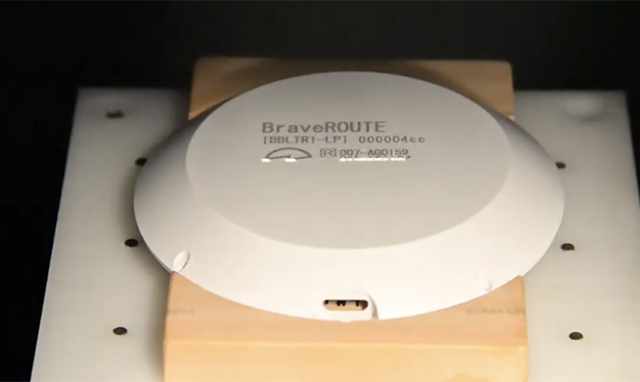

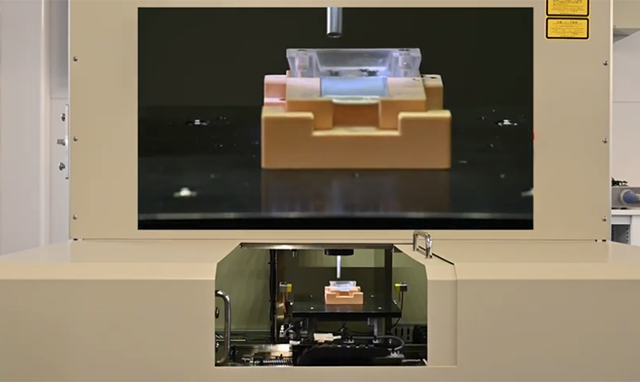

1 In-House Jig Production

All jigs used for assembly and inspection in the manufacturing processes are made in-house. We are also able to make customised jigs, and take orders for jigs alone.

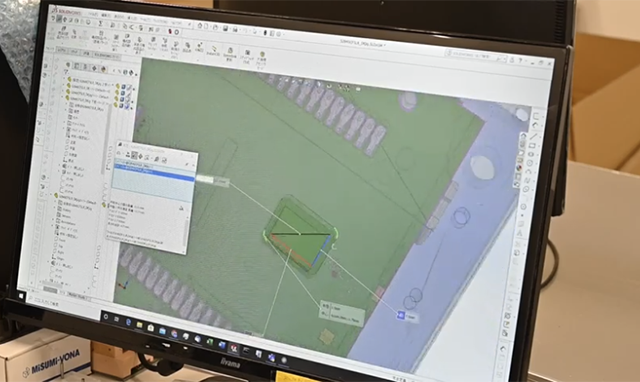

Jig Design

Jig Production

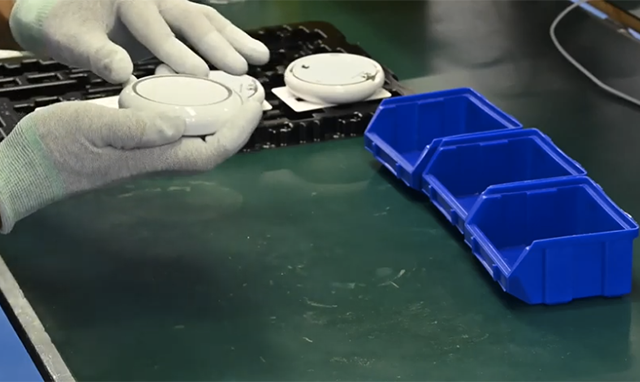

Scenes of a Jig in use

2 Procurement

With our established networks, we procure parts from Japan and across the world.

Procurement Network

From mechanical to electronic parts, we are able to purchase high-quality parts with reasonable prices from all over the world. We practice 100% self-procurement.

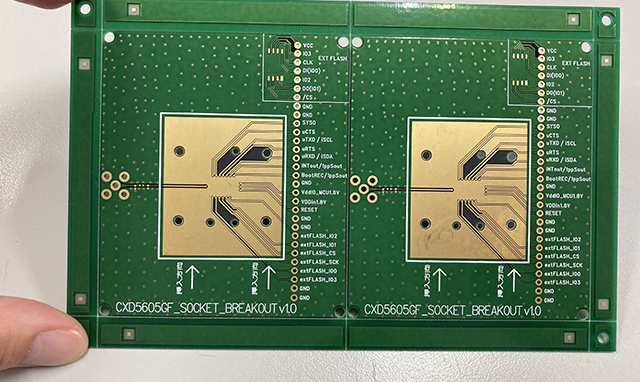

PCB

Circuit Boards are designed through numerous discussions between head office and factories both in Japan and abroad.

Mold

We have signed contracts with a few mold factories in China, Vietnam and South Korea. The most suitable factories are selected according to the schedule and requirement of the production.

Container Acceptance

3 Contract Manufacturing

We also accept partial manufacturing contracts. Please contact us for assembly matters.

Assembly

Processing

Bond Application

To stabilize quality and to pursue work efficiency, coating robot is in full shift to perform optimum coating.

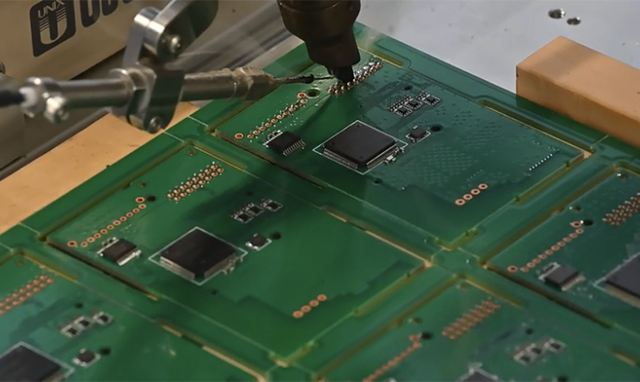

Automatic Soldering Equipment

Automatic soldering equipment operates effectively when mass production and efficiency in manufacturing process are required.

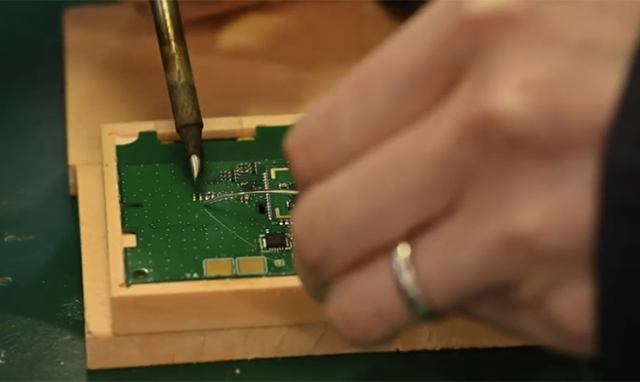

Hand Soldering

We have introduced a certification system for hand soldering, where only certified personnel can work. This certification is renewed once a year to improve the skills of the workers.

4 SMT

Super small size 0402 is also mountable. (Processed at a cooperating factory with quality assurance agreement.)

SMT

5 Speedy Shipping

Thanks to the assembly in Japan, delivery can be made within a few days once the production is complete.